Electrical Vehicle DC Fast Chargers Littelfuse Mouser

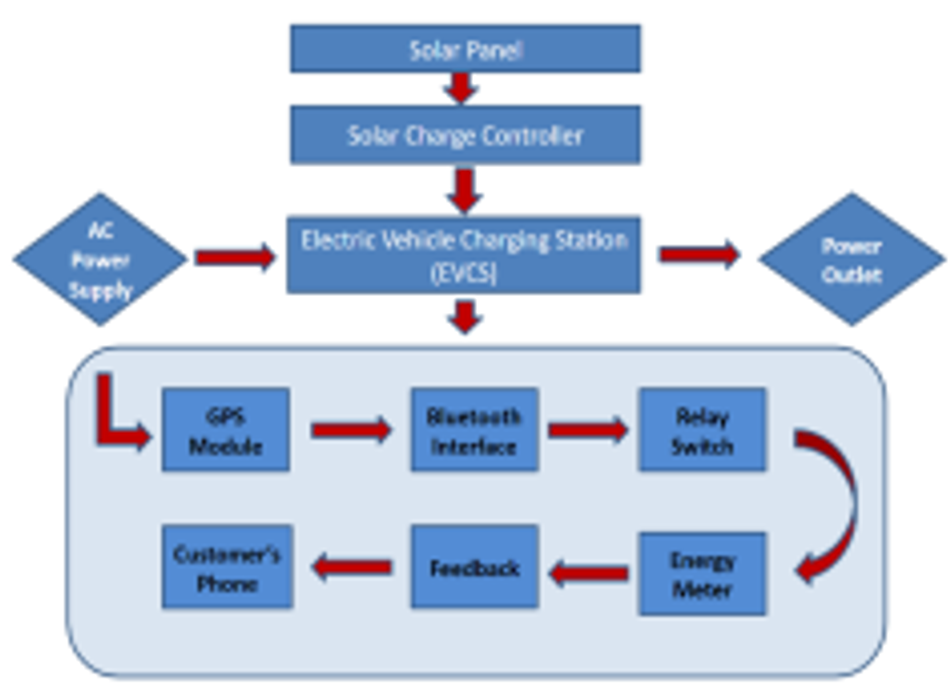

Download scientific diagram | 8: Block diagram of an Electric Vehicle Charging Station. from publication: OPTIMIZATION OF HYBRID RENEWABLE ENERGY BASED ELECTRIC VEHICLE CHARGING STATION |.

Electric Vehicle Charging Station Circuit Diagram Pdf Wiring Diagram

. block diagram of a typical inductive EV wireless charging system is shown in Figure 1, following the standardized stationary wireless EV chargers model presented in the SAE J2954.

Electric Vehicle (EV) Charger Solution Renesas Mouser

Download scientific diagram | General block diagram of DC fast-charging station from publication: Energy-efficient converters for electric vehicle charging stations | The rise in the number of.

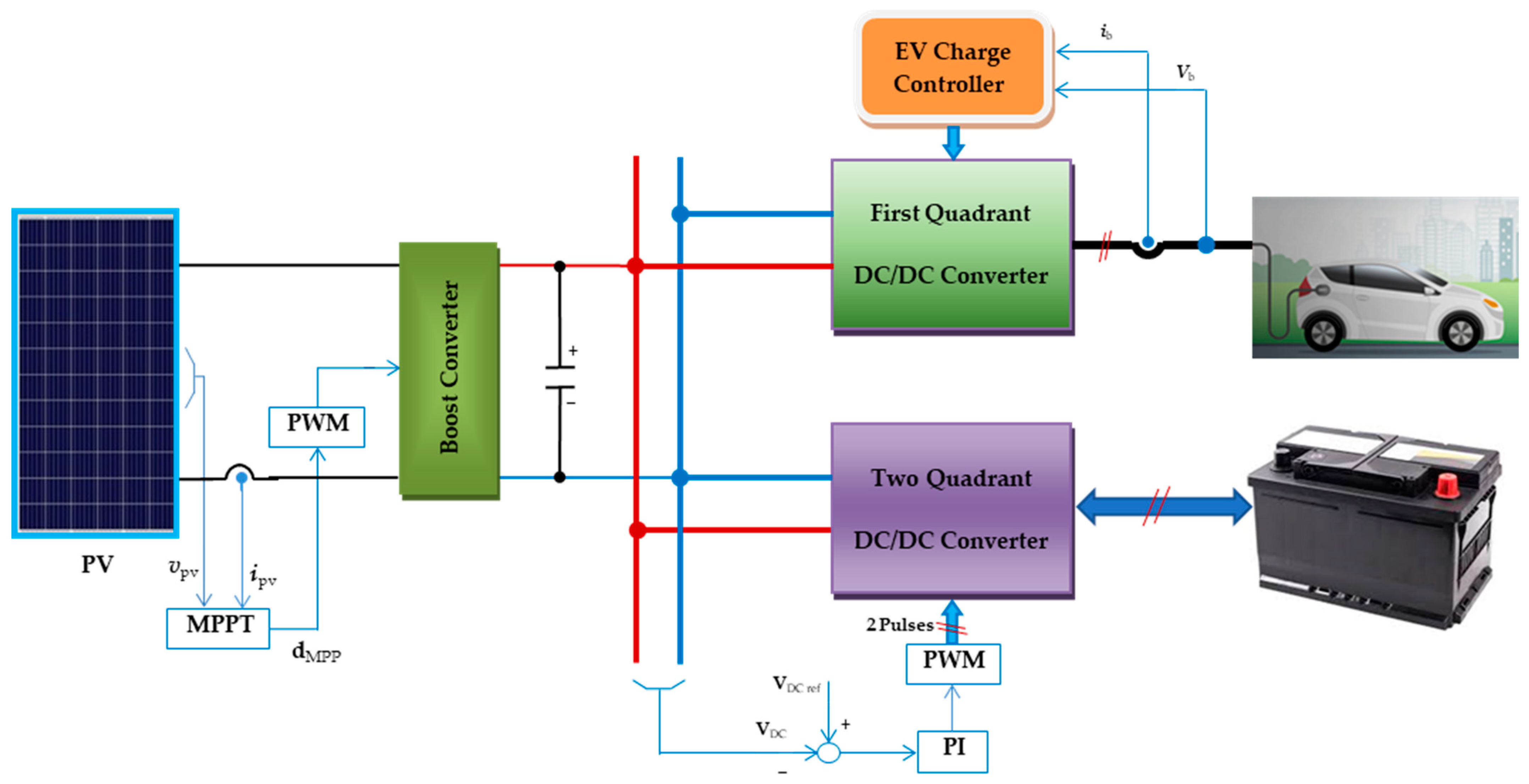

Electric Vehicle Charging Station from Public Electricity and Solar Panels

System level control is another important area and the 25 kW fast charger features multiple closed-loop controllers within the PFC and DAB to control parameters such as transformer active flux balancing and primary to secondary phase shifts to control output voltage and current. One challenge here is selecting the gain for each loop, so that.

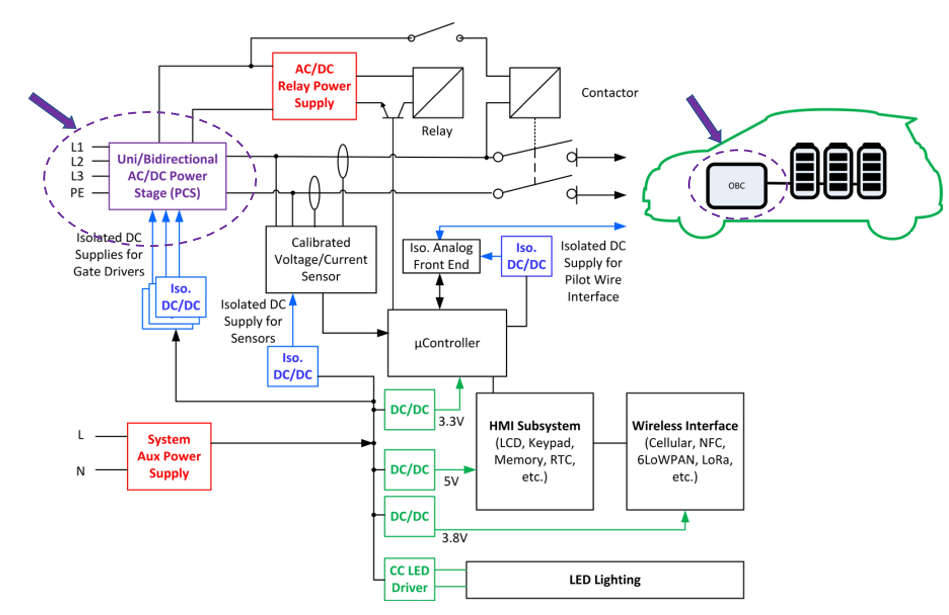

OnBoard Charger Microchip Technology

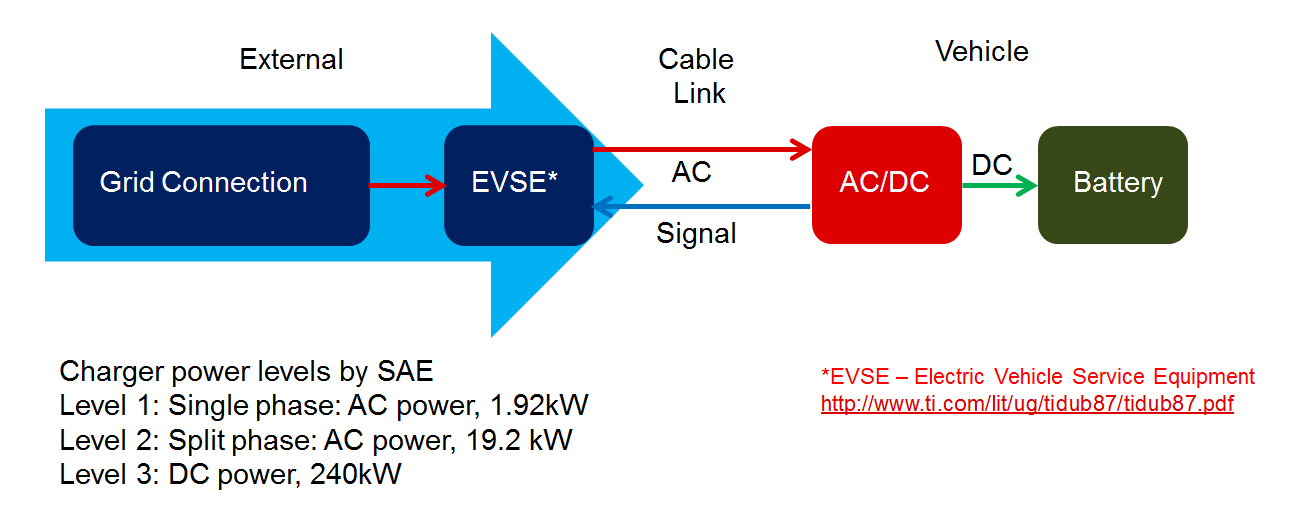

Charging for EVSE level 3 is different from levels 1 and 2 because the charger is located inside the EVSE. Figure 4 shows a typical level 3 block diagram. Click image to enlarge. Figure 4: Typical level 3 EVSE block diagram . The level 3 EVSE in Figure 4 uses 24 V instead of 12 V for the main power rail.

Typical EV onboard battery charger topology based on a totempole PFC.... Download Scientific

2 ELECTRIC VEHICLE COMPONENTS. A typical block diagram of the EV is shown in Figure 1. Each block is designed for specification and topology suitable for its required applications. The existing battery charging topologies are listed subsequently in Table 1.

Block Diagram (SBD) EV HEV Charger level 3 Electronic Products

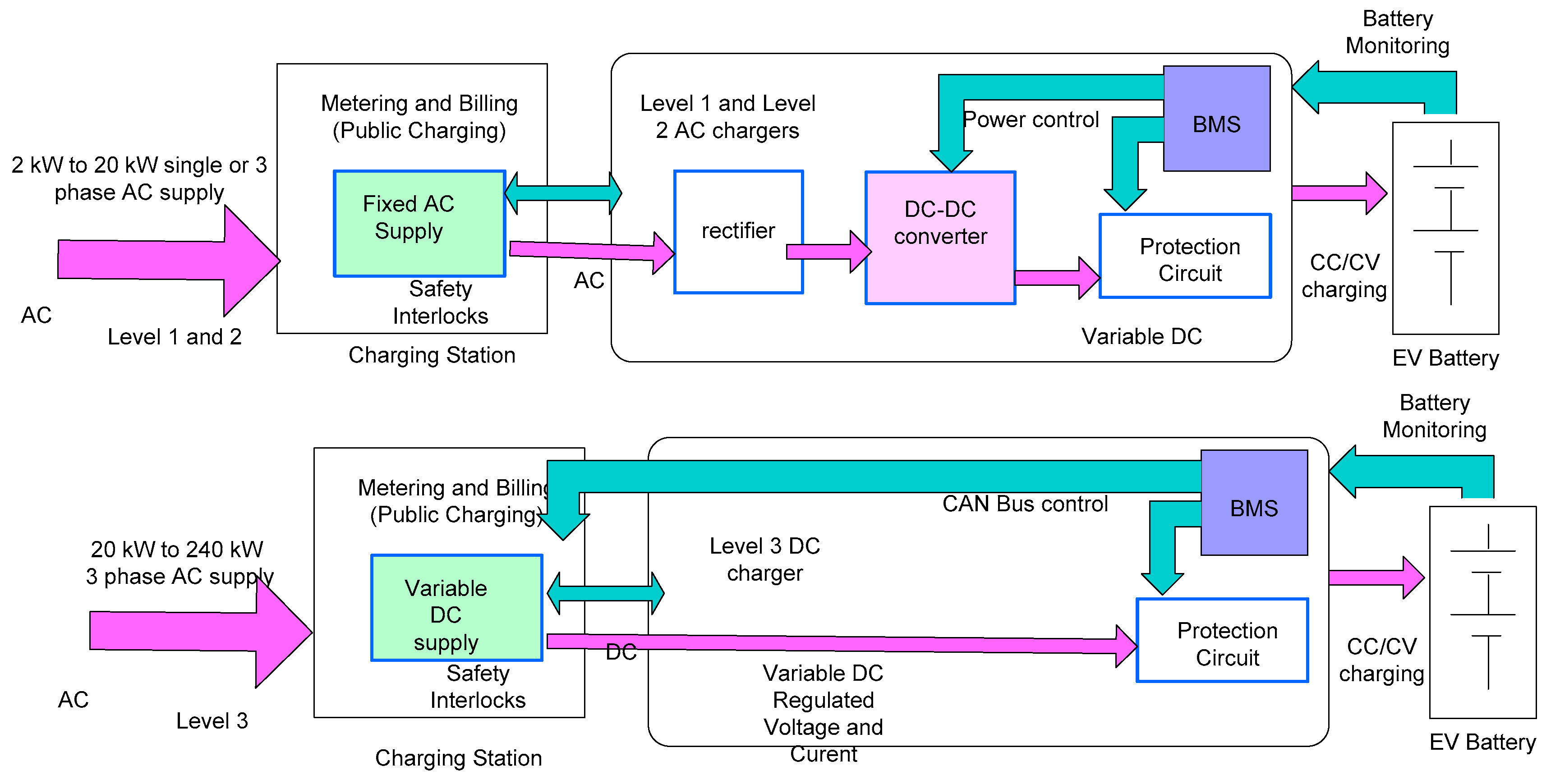

20-30 minutes of charging will add approximately 90-100 miles of travel. DCFC EVSE directly converts AC power to DC power, bypassing the EV's On-Board Charger to deliver high DC current into the PEV's traction batteries. DCFC EVSE is connected directly onto the charging inlet of the Vehicle. For this block diagram, we will focus our.

Ev Charging Circuit Diagram Wiring Diagram

Block Diagram (SBD) EV HEV Charger: level 1 & 2 Posted on November 6, 2013 by Electronic Products Design Considerations Plug-in Hybrid Electric Vehicles (PHEV) and Battery Electric Vehicles (BEV) are two quickly emerging technologies which use powerful electric motors and high voltage battery packs as the propulsion and energy sources.

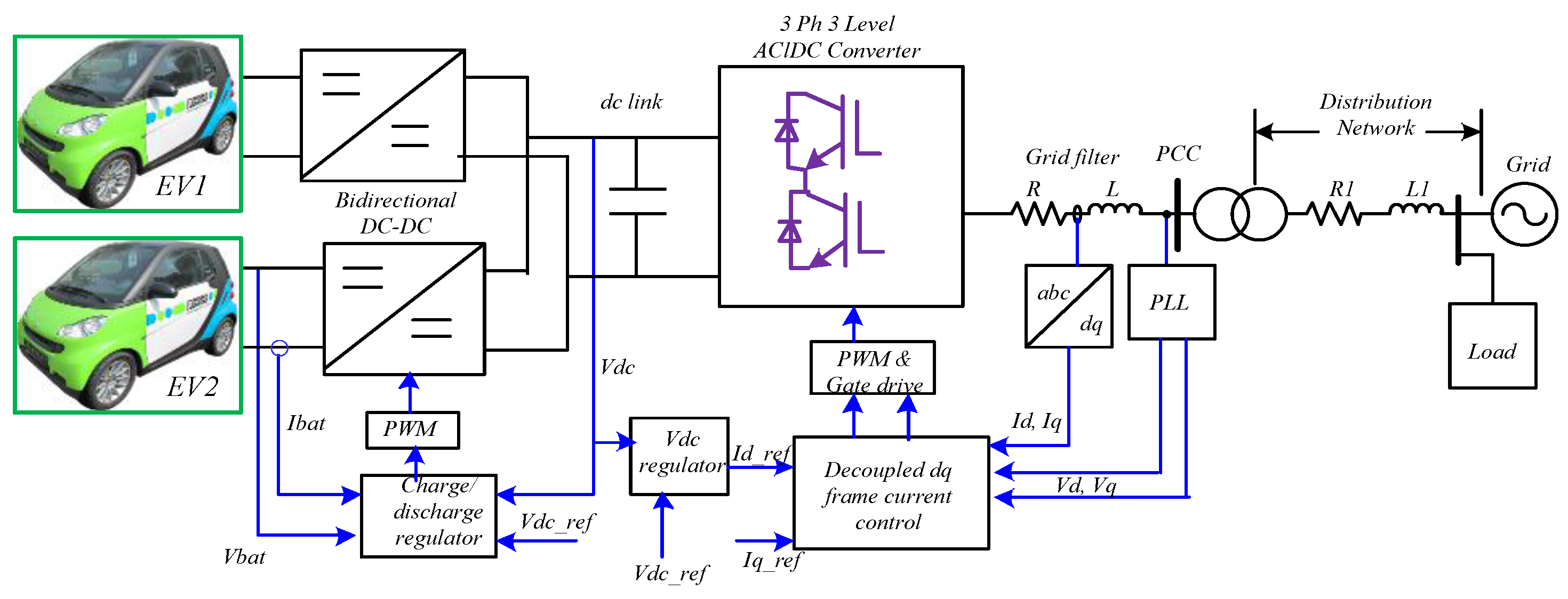

Bidirectional Designs to Reduce Carbon Footprint in EV

Figure 2-1 shows the system level block diagram of a EV charging station power module captured from TI's EV charging station power module, web page. On the input side it has three-phase AC mains which are connected to the AC/DC power stage. This block converts the incoming AC voltage into a fixed DC voltage of around 800 V.

Energies Free FullText Optimum Resilient Operation and Control DC Microgrid Based Electric

A typical block diagram of an EV on-board battery charger is shown in Fig. 1 which illustrates the two converters; AC-DC converter with Power Factor Correction (PFC) [15,16] followed by an.

Proposed block diagram of the PV based Offgrid charging station with... Download Scientific

EV Charging EV-CHARGING Last Updated: Oct 26, 2023 An Electric Vehicle (EV) charging station supplies power for recharging electric vehicles. Typical EV charging stations are made up of at least one smart controller board and one power socket board. The smart controller manages security, services and connectivity to a remote server and

Design Essentials for Smart EV Charging System Control Free Online PCB CAD Library

An Electric Vehicle (EV) charging station supplies power for recharging electric vehicles. Typical EV charging stations are made up of at least one smart controller board and one power socket board. The smart controller manages security, services and connectivity to a remote server and the power socket board distributes and measures energy.

HOLTEK introduces smart battery charger solution in the Indian EV market

EV chargers use a simple "pilot" signal to detect when they are plugged into a car and to tell the car how much current it is allowed to draw from the charger. They don't modify the mains at all, they just switch it on/off to the car via some relays. In addition to this they also incorporate the functionality of an RCD.

Are you onboard? Demystifying EV charging systems Power House Blogs TI E2E Community

EV Charging Block Diagram Full Product Recommendation Table Solution Description Interactive Block Diagram (onsemi.com) 3-Phase Rectifier / PFC Topology 1 - Less components, higher efficiency, 1200 V diodes, requires 6 switches. Topology 2 - Cost effective, 600 V diodes, requires only 3 switches but diodes are in series, hence the lower efficiency.

matlab circuit simulation

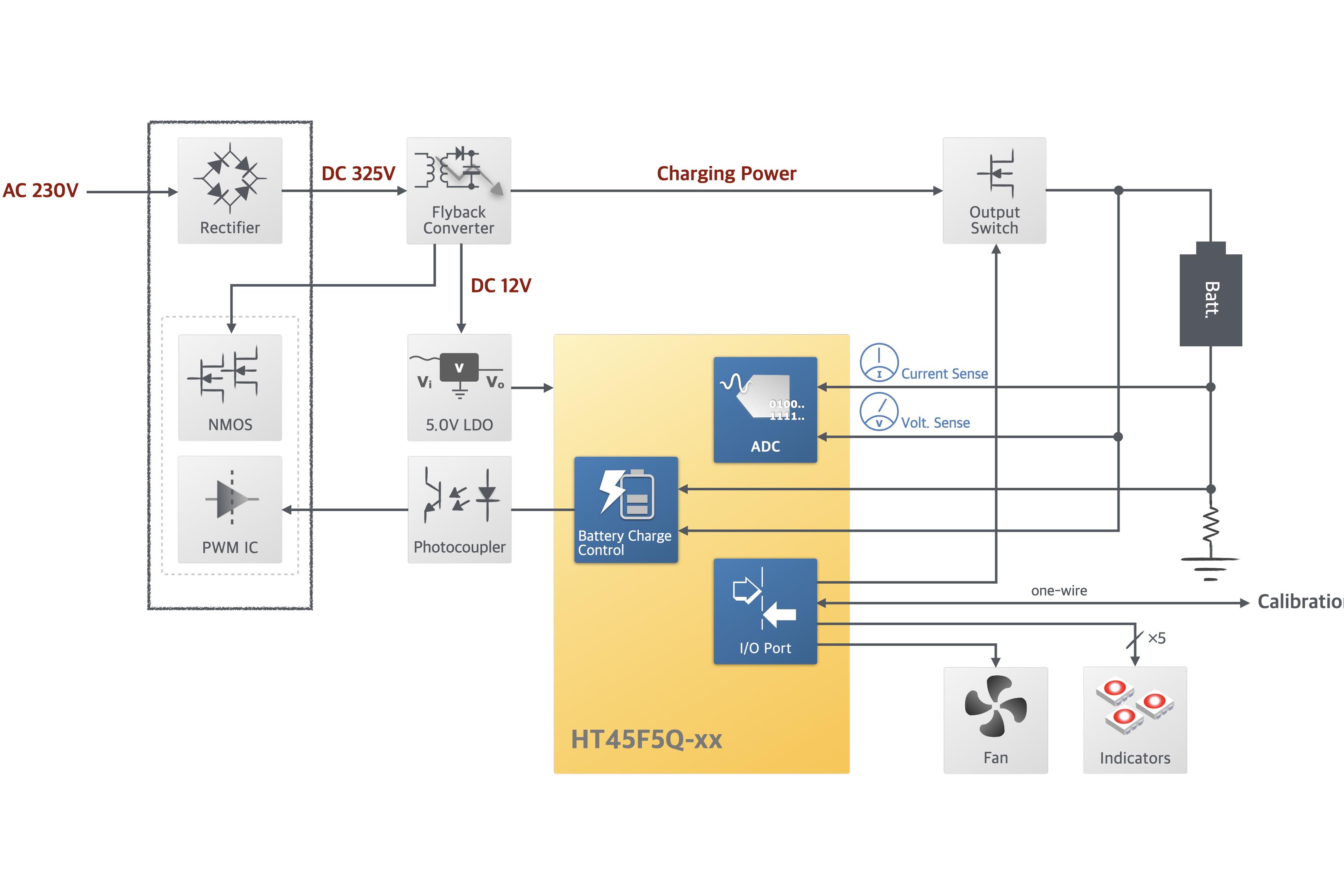

Fig. 1: EV charger block diagram Designers can choose an appropriate MCU from the HT45F5Q-X series according to their application requirements. Specifications of the battery charger flash MCU HT45F5Q-X series are shown in Fig. 2. Fig. 2: HT45F5Q-X specifications

Block Diagram (SBD) EV HEV Charger level 1 & 2 Electronic Products

An EVSE is designed and engineered to charge a battery pack by using the grid for Power Delivery; these battery packs might be present in an Electric Vehicle (EV) or in a Plug-in Electric Vehicle (PEV). The power, connector and protocol for these EVSE will vary based on it design which we will discuss in this article.